Technology & Innovation

Over the past years, CWPL is on a rampant journey to lead in its vast variety of product portfolio with the help of its strong sense of product design, tool design, tool development, technology in wheel manufacturing and wheel testing. We have the largest product range and are proud to be manufacturing wheels for India’s smallest Tractor, biggest tractor and widest single piece wheel in INDIA.

At Carrier Wheels Pvt. Ltd., we have a dedicated R&D Center approved by the Department of Scientific and Industrial Research (DSIR), Ministry of Science and Technology, Government of INDIA. Our team is continuously working towards innovation, product improvement, process improvement and new product development. CWPL has helped many of it’s OEM customers to indigenize their sourcing of wheels from INDIA by developing an alternate design to their existing imported product. CWPL has also been a preferred supplier for many of it’s OEM customers for new product development and has been at the forefront to develop wheels for innovative products like the first electric tractor, first hybrid tractor, first lawn tractors developed in INDIA.

CWPL is at the forefront in exploring and developing technologies, designs and enhancements for the future. We believe in constantly setting up higher benchmarks while adding value to our product without compromising on the function of our products. To achieve this, VAVE (Value Analysis and Value engineering) is one of the core methodology to evaluate and establish new designs and innovate.

- Innovative Twin lug with bridge design

- Technology developed in house to weld lug to large diameter wheels

- Technology developed in house to weld lug to small diameter wheels

- Introductoion of tubeless wheels upto 38 inches in Dia

- Early adopter of technology to check online runout for 100 percent wheels in its production line for wheels from 12 inches to 38 inches

- All welding is done using advanced CNC or PLC controlled SPM’s

- Development of single piece wheels upto 20 inch wide

RFT (Radial Fatigue Test)

CWPL has one of the largest RFT machine in the country to test wheels upto 44 inches in diameter. Specified load and speed conditions can be applied to the wheel in mounted condition to ensure it meets the customer requirement. CWPL believes in extensive testing of the wheels during the development stage to ensure customer confidence.

CFT (Cornering Fatigue Test)

CWPL has one of the largest CFT machine in the country to test wheels upto 38 inches in diameter. Specified load and bending moment conditions can be applied to the wheel to test the strength of the wheel. CWPL ensures that wheels tested and produced meet the specifications and the only once the wheel is tested successfully and has proved its lifecycle capability, it is approved for production and delivery to the OEM’s.

CMM (Coordinate Measuring Machine)

CWPL has the capacity to test that the first off wheel produced is manufactured as per the customer requirement and inspections can be done at micron levels. Any critical tool developed at CWPL is also inspected at the CMM to identify deviations at early stages of development to avoid project delays. We believe that correct observations at the initial stages can help save time and help us deliver First Time Right product to the customer.

ROT (Run Out Testing)

Hundred percent of our wheels are inspected using automatic Run Out Testing machines to ensure that each and every component is within the required specification and auto dimensioning of each rim and valve hole presence is carried out for each part. Auto rejection of non-compliant component and alarm by the machine ensures that non-compliant part is rejected at the machine itself. We believe in enriching our customer experience such that there is a zero inspection requirement at customer end so that our wheels can be confidently adopted and mounted on the vehicle.

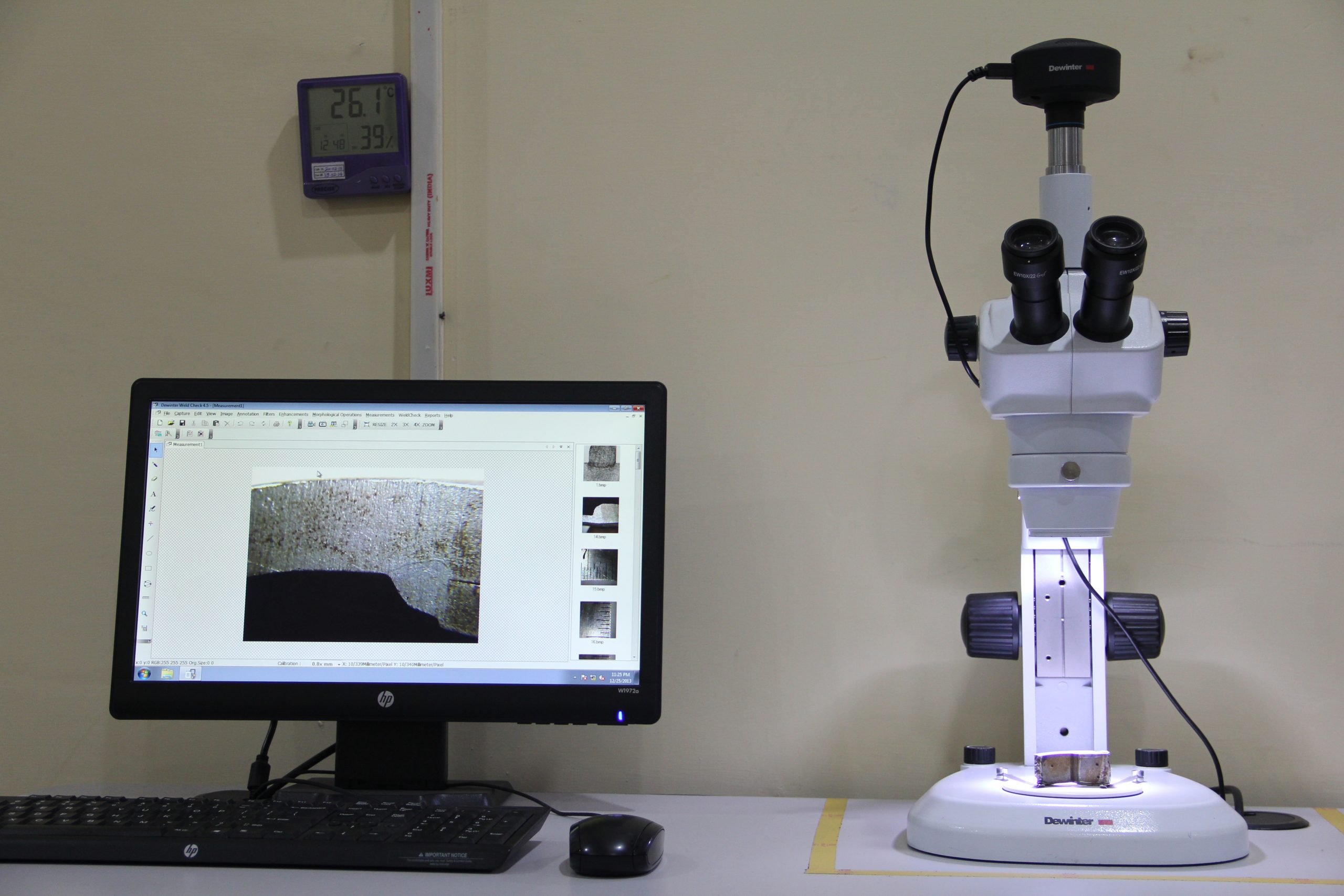

Weld Penetration Testing

Hundred percent of our wheels are inspected using automatic Run Out Testing machines to ensure that each and every component is within the required specification and auto dimensioning of each rim and valve hole presence is carried out for each part. Auto rejection of non-compliant component and alarm by the machine ensures that non-compliant part is rejected at the machine itself. We believe in enriching our customer experience such that there is a zero inspection requirement at customer end so that our wheels can be confidently adopted and mounted on the vehicle.

SST (Salt Spray Test)

Paint is an important aesthetic and corrosive resistance partner to the wheel and to ensure long term paint life, CWPL uses Salt Spray Test to test the life of the paint in terms of rust prevention and rust penetration. CWPL uses a number of other different tests for paint validation in order to ensure that the paint specifications are as per requirement. CWPL uses the most advanced primer coating through electro coating (CED – Cathode Electro Deposition) and TSA/PU paints to achieve long paint life without compromising on the aesthetic appearance.

Learn more

Technology & Innovation

Improving our Technology and constantly innovate is what we aim for.

Quality Control & Assurance

At CWPL, Quality product is a commitment, a duty and a priority. Quality is caused and not controlled.